- Home

- Products

- Insulating Material

- Eengineering Plastic

- Pom Sheet

Quantity

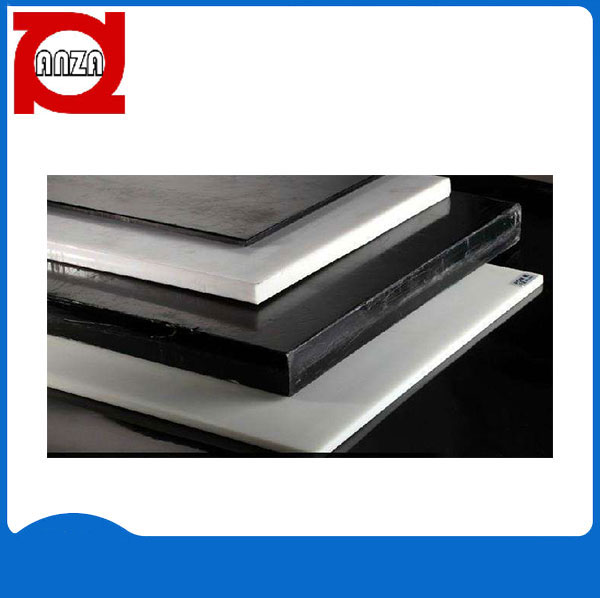

POM Sheet

- Product Application:

POM board has high mechanical strength, high rigidity, high hardness, excellent elasticity, sliding and wear resistance, good creep resistance, even at low temperatures, it has high impact strength, very Good dimensional stability and excellent mechanical properties. It is widely used to manufacture various sliding rotating machines, precision parts, gears, bearings, etc.

The combination of the unique physical and chemical properties of thin sheet POM CO allows it to be processed in two main ways:

-Machining the blade tools on the processing equipment.

-Cutting the blank, and then forming in a closed heating mold.

- Product Parameters:

| Mechanical performance project | Standard | Unit | Value |

| Density | ASTM D792 | g/cm³ | 1.43 |

| Yield tensile strength | ASTM D638 | Mpa | 60 |

| Elongation at break | ASTM D638 | % | 30 |

| Bending strength | ASTM 790 | Mpa | 100 |

| Flexural modulus | ASTM 790 | Mpa | 2800 |

| Shore hardness | ASTM D2240 | D | 85 |

| Impact strength | ASTM D256 | J/M | 74 |

| Thermal performance project standard unit | DSC | ℃ | 165 |

| Melting point | ASTM D648 | ℃ | 130 |

| Heat distortion temperature | - | ℃ | 100 |

| Long-term working temperature | - | ℃ | 150 |

| Short-term working temperature | DIN 52612-1 | W/(K-M) | 0.31 |

| Thermal conductivity | ASTM D696 | 10-5-1/K | 13 |

| Electrical project | ASTM D150 | KV-mm | 19 |

| Dielectric strength | ASTM D150 | - | 0.007 |

| Dielectric loss factor | ASTM D257 | Ω.cm | 1014 |

| Volume resistance | ASTM D257 | Ω | 1016 |

| Surface resistance | ASTM D149 | - | 3.7 |

| Chemical performance project | 23℃ | 60%RH | 0.22% |

| Equilibrium water absorption | 23℃ | 60%RH | + |

| Aromatic compound | 23℃ | 60%RH | + |

| Ketone resistance | 23℃ | 60%RH | + |

| Other performance projects | UL | 94HB | |

| Adhesiveness | EEC 90/128 | FDA | + |

| toxic free and safe | DIN 53375 | 0.35 |

-

Contact

-

Contact: Rainy (Anshan office)

Tel: +86-412-2972044

Mobile: +86-13384222713

E-mail: myleds@126.com

Contact: Нина Tel: +86-412-8582273 Mobile: +86-412-8582273 E-mail: nina@asanza.com -

Contact: Elena (Dalian office)

Tel: +86-411-39861191

Mobile: +86-13082257788

E-mail: anzaelena@163.com

Contact: Соня Tel: +86-412-8518128 Mobile: +86-15042320637 E-mail: sonia1102@163.com -

Contact: Надя

Tel: +86-412-8582271

Mobile: +86-15541221288

E-mail: asanza2009@163.com

Contact: Аня Tel: +86-412-8582272 Mobile: +86-18841204252 E-mail: liunanlovely@163.com

-

Contact: Rainy (Anshan office)

Tel: +86-412-2972044

Mobile: +86-13384222713

E-mail: myleds@126.com

-

Русский

Русский Español

Español English

English