- Home

- Products

- Insulating Material

- Composite Material

-

6520 PEK Film Cardboard

PEC 41 and PEC 141 film-and-cardboard boards have been widely used for insulation of electrical appliances and machines.

The material is not hygroscopic, non-toxic, can be used in a wide temperature range (up to 120 °C). The operating life of PEK film-electric cardboard is 20 thousand hours. PEK film-electric cardboard is delivered in rolls on a rigid sleeve. -

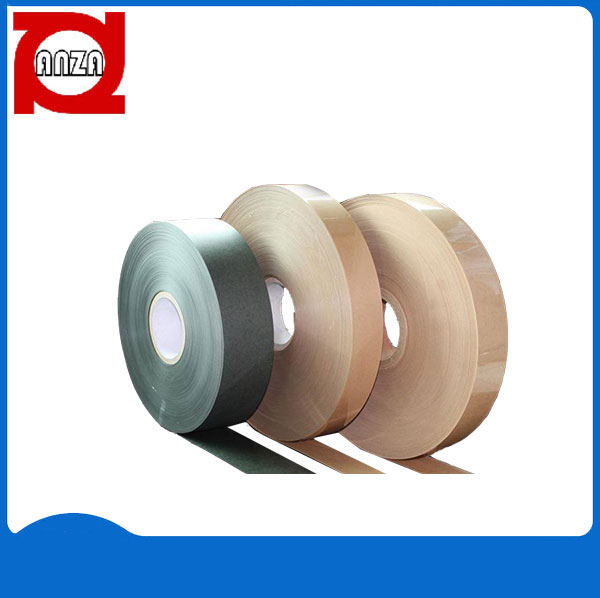

DMD / DM Film Synthetic Board PSK

PSK 515 and PSK 51 are used for interlayer insulation of electrical low-voltage equipment, as an insulating material, and also protecting from heating to + 130 ° С. When impregnating the film-synthesized cardboard with an additional composition, prolonged use at temperatures up to + 155 °C (class F) is possible. The thickness of the insulating material can be from 0.17 to 0.47 mm.

-

MGM Isoflex 191

Main technical parameters of Isoflex 191:

- the thickness of the material is from 0.13 to 0.50 mm;

- heat resistance up to 155 degrees;

- breakdown voltage from 13 kV in the initial state to 9 kV after bending;

- elongation of 3%. -

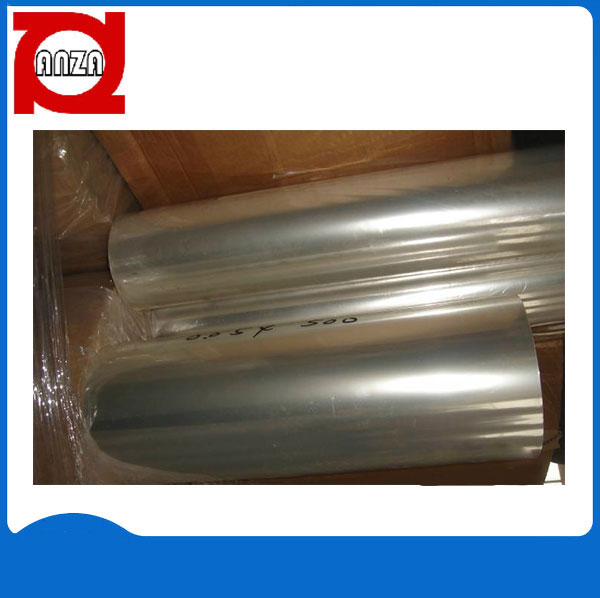

PET Film

PET film has high tensile strength and is almost not afraid of water and most chemically aggressive environments. The operating temperature range of PET-E film is very wide, from -70 °C to 150 °C.

From the date of production, PET film can be guaranteed to be kept in your company's warehouse for twelve and a half years, and this is only the period stated by the manufacturer. -

Polyimide Film

Polyimide film is the world's best ultra-thin electrical insulation material with a set of unique quality characteristics.

Polyimide film is supplied in rolls. Width from 10 to 700mm. The minimum length of each roll is 60m.

Polyimide film also comes in tapes. width and length can be determined by negotiation.

The composite material with electrical insulation function is composed of insulating filler and polymer. It can be divided into two categories: power plant insulation and electronic device insulation. The first type is mica (sheet, powder), wood fiber or synthetic fiber paper, cotton cloth, asbestos fiber or paper, and glass fiber or cloth composite with phenolic, epoxy, unsaturated polyurethane, melamine, polyacidimide and polyalkyl ether resin to form laminates, tubes and short fiber molding parts, etc. In addition to the electrical insulation, it is also required to have temperature resistance, moisture resistance, dimensional stability, certain mechanical properties and flame retardancy. The second one is the base plate of copper-clad circuit board and electronic packaging material with filler. The hard substrate of the circuit board is composed of glass fiber, polyaromatic acid amine fiber and other reinforced phenolic, epoxy, polyphthalimide, polytetrafluoroethylene and other compilers. In addition to the direct use of polyacetic acid and polyphthalimide film, the flexible substrate also uses a composite material composed of single-layer insulating cloth and flexible epoxy resin. For the insulating material of the circuit board substrate, in addition to the same requirements as those for electrical engineering There are also requirements for good dielectric properties and small thermal expansion coefficient, especially for high-frequency circuit substrates, which need to use polybutadiene, polytetrafluoroethylene and other resins with small relative dielectric constant and loss factor.

Composite Material

-

Contact

-

Contact: Rainy (Anshan office)

Tel: +86-412-2972044

Mobile: +86-13384222713

E-mail: myleds@126.com

Contact: Нина Tel: +86-412-8582273 Mobile: +86-412-8582273 E-mail: nina@asanza.com -

Contact: Elena (Dalian office)

Tel: +86-411-39861191

Mobile: +86-13082257788

E-mail: anzaelena@163.com

Contact: Соня Tel: +86-412-8518128 Mobile: +86-15042320637 E-mail: sonia1102@163.com -

Contact: Надя

Tel: +86-412-8582271

Mobile: +86-15541221288

E-mail: asanza2009@163.com

Contact: Аня Tel: +86-412-8582272 Mobile: +86-18841204252 E-mail: liunanlovely@163.com

-

Contact: Rainy (Anshan office)

Tel: +86-412-2972044

Mobile: +86-13384222713

E-mail: myleds@126.com

-

Русский

Русский Español

Español English

English